Increased Safety:

Reduces personnel exposure by minimizing Confined Space Entry requirements.

Cost Reduction:

Minimises plant preparation, leading to a reduction in shutdown costs.

Improved Inspection Repeatability:

Reduces shutdown times by enhancing the consistency and reliability of inspections.

Non-Intrusive Inspections:

Eliminates the need for intrusive inspections, contributing to a safer and more efficient process.

Streamlined Permit and Isolation:

Reduces the requirements for permits and isolations, streamlining operational processes.

Enhanced Inspection Coverage:

Improves maintenance planning by increasing inspection coverage.

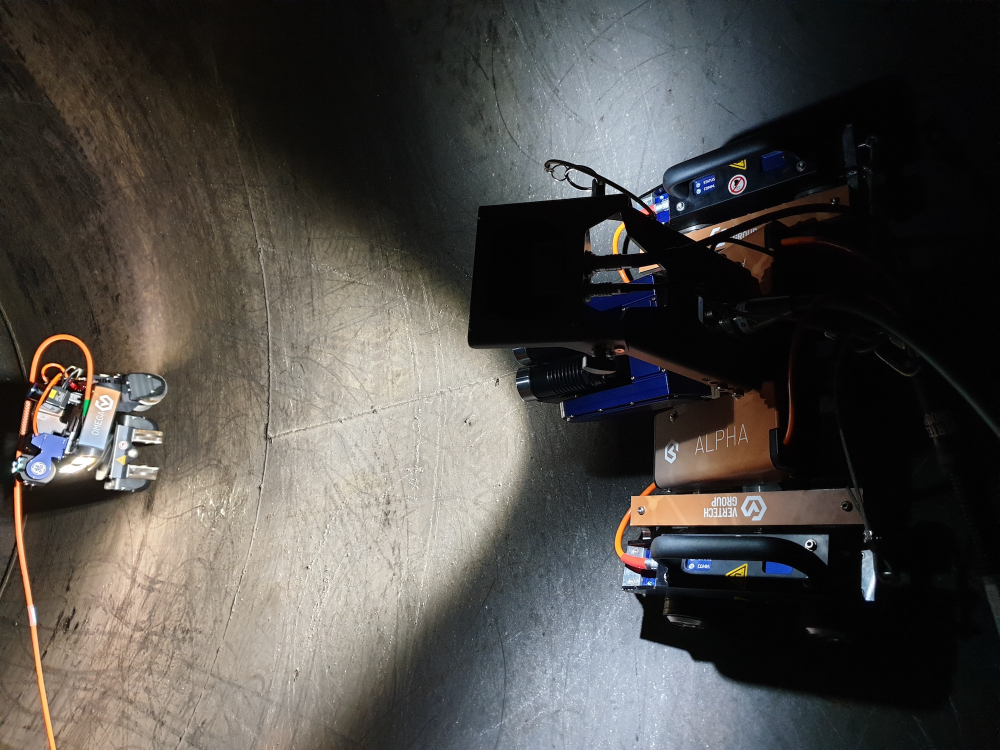

Utilisation of Latest Technology:

Leverages cutting-edge robotics, cameras, and crawlers, staying at the forefront of technological advancements.

Alignment with Non-Intrusive Inspection (NII) Techniques:

Aligns with other Non-Intrusive Inspection techniques, fostering a holistic and integrated approach.